| Availability: | |

|---|---|

| Quantity: | |

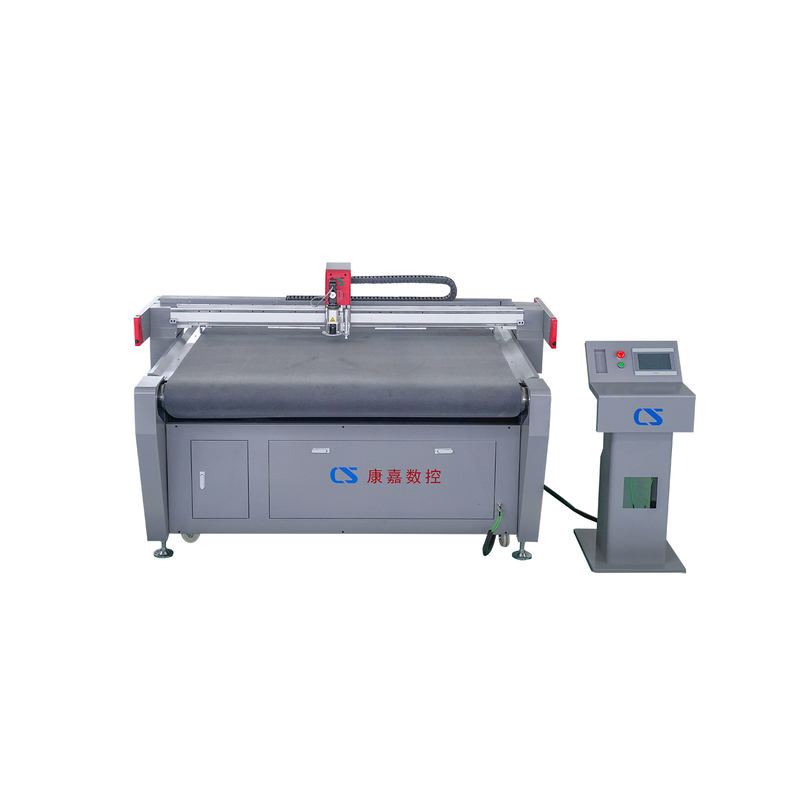

CTS-SL1615

kangjia

1. Emergency button device. When the machine breaks down during work, the machine will stop working as soon as it is pressed, which is safer.

2. There is a new laser shooting emergency stop device with four laser beams. As long as the laser beam is blocked, the machine will automatically stop working to avoid the human body being injured by the moving tool head or the material being tilted and jamming the tool head.

3. Taiwan PMI linear guide rails and polyurethane synchronous belts ensure smooth cutting while the machine operates at high speed, achieving fast and precise cutting with a speed of up to 1400mm/s.

4. Control panel: 16 contact buttons and LCD display, which can realize all fine-tuning functions of the machine.

5. Multi-functional cutting head, which can be configured with different heads according to different material properties to meet different customer needs.

6.Using imported Schneider inverter, it saves 30% electricity than its peers.

7. Integrated welded frame (guaranteed not to loosen for many years), integrated 42MM thick aluminum alloy platform (guaranteed level), and polyurethane timing belts and guide rails used for transmission.

8. Various methods of adsorbing and fixing materials (comprehensive adsorption, follow-up adsorption, zoned adsorption) can be freely switched according to material properties.

9. Computer automatic typesetting, adjustable to any width, any angle, multiple pieces can be freely combined and mixed for zero-distance typesetting to improve the maximum utilization of materials.

1) General description of the equipment body

1) General description of the equipment body

The equipment sub-assembly and main core components are divided into the following parts: automatic cutting machine host, automatic typesetting software, electronic control system, vacuum pump, linear guide rail, vibrating cutter head, driver, motor, gear rack, discharge rack, etc.

2) Mechanical frame part

2.1. The cutting table is an all-cast aluminum vacuum cavity aluminized plate socket nail drilling platform + high-density fiber felt;

2,2. The main bracket is a welded steel structure;

3) Power drive part

3.1. The X and Y axes all adopt belt width transmission to meet the requirements of long-term cutting;

3.2. Use internationally renowned brushless servo motors and X-direction unidirectional motor drives to ensure equipment stability and cutting accuracy;

3.3. It has excellent continuous operation capability and can operate continuously 24 hours a day, 7 days a week, without shutting down for cooling;

4) Host cutting part

4) Host cutting part

4.1. The cutting equipment adopts single-layer cutting, and the cutting method is high-frequency vibrating knife/active wheel knife, etc.;

4.2. The computer automatic cutting control system adopts a network-based distributed digital control system rather than an analog system;

4.3. The equipment is equipped with vibrating knife cutting. Different cutting heads (circular knife, punching knife, pneumatic knife, punching knife, etc.) can be equipped with different cutting blades according to different materials to cut various flexible materials. Also equipped with a marking pen;

4.4. The cutting bed area of the equipment can adapt to cutting of different widths and is easy to replace and adjust;

4.5. The machine can be paused at any time during automatic cutting. After the pause, the machine head and cutter head can move arbitrarily. After resuming automatic cutting, the cutter head will automatically return to the pause point to continue cutting without the need for manual secondary positioning;

5) Electrical control part

The components configured in the equipment's electrical control system adopt internationally renowned brands, such as Panasonic, ALPHA, CHNT, DELIXI, Inovance, Omron and other brands.

APPLIED MATERIALS

APPLIED MATERIALS

Applied to various industries such as industrial leather, plastics, rubber, sponge, foam, EVA, PVC, cardboard, paper products, fabrics, home textiles, packaging materials, non-woven fabrics, carpets, car cushions, felt, synthetic materials, and other non-metallic materials.

Model | CTS-SL1615 | CTS-SL1625 |

Power | 9KW | 9KW |

Voltage | 110V/220V/380V±10%,50HZ 60HZ | 110V/220V/380V±10%,50HZ 60HZ |

Cutting speed max | max 1400mm/s | max 1400mm/s |

Cutting thickness | ≤50mm | ≤50mm |

Effective cutting area | 1500*1600(L*W) | 2500*1600(L*W) |

Cutting accuracy | ±0.1mm | ±0.1mm |

Cutting Materials | Flexible Materials | Flexible Materials |

Material fixation method | vacuum adsorption | vacuum adsorption |

Transmission interface | USB /inernet port | USB /inernet port |

Compatible software | KANGJIA software | KANGJIA software |

Control system | LED touch screen | LED touch screen |

Drive motor | Panasonic | Panasonic |

Operating mode | automatic | automatic |

Rail | PMI | PMI |

Architecture | integrated framework | integrated framework |

Certification | CE/SGS,ISO9001 | CE/SGS,ISO9001 |

Safety device | emergency stop button, infrared beam, anti-collision | emergency stop button, infrared beam, anti-collision |